Six Sigma represents the business world’s initiative to iteratively improve processes and quality. Though newer layers keep getting added to it, the strategy is founded on solid principles of total quality and continuous improvement. It has found new relevance in new-age businesses while it continues to unearth efficiencies in traditional businesses. Hence, there has been a renewed interest in Six Sigma lately.

To understand how it helps and can be implemented, let’s explore Six Sigma in detail, including its principles, methodologies, techniques, examples and its variations.

What Is Six Sigma?

Six Sigma is a method that provides ways to achieve process improvement in terms of high quality and efficiency by minimizing variation, defects and errors.

It aims to attain near-perfect quality, allowing for only 3.4 defects per million opportunities. Developed by Motorola in the 1980s, the methodology uses project management, financial analysis and statistics to iteratively improve business processes.

It finds application in a wide range of industries like service, manufacturing, healthcare, finance etc. Besides improving quality, it’s effective in increasing customer delight, cost-efficiency and profits.

What’s the Importance of Six Sigma?

Over the years, this method has become a powerful quality benchmark in a variety of ways. Let’s discuss these in detail.

Foster Continuous Improvement Culture

Often, valuable time and efforts are wasted because the team members lack insight into their role in the project and how they can better assist the team. By conducting process mapping, the teams can analyze every step in the process and see how it impacts customer delight. All of this enables companies to nurture a culture that fosters continuous improvement.

Eliminate Variation and Wasteful Efforts

As business processes are standardized, it’s possible to reduce variation iteratively and eventually eliminate it. However, if removing the effort doesn’t result in any problems, its continued presence must be questioned. With Six Sigma, it’s easier to locate efforts that don’t contribute to product/service quality and delivery and remove them.

Reduce Inefficiencies

Six Sigma can be used to improve work efficiency, whether at a service firm or a manufacturing unit. It helps automate processes to the best extent possible and enables continuous expansion of automation possibilities. As a result of better efficiency, there are significant improvements in timeliness too.

Improve Compliance

In addition to the above, Six Sigma helps companies comply with the Service Level Agreements (SLAs) that they have agreed upon with their customers. It enables companies to proactively identify deviations from project plans, budgets and outcomes. It facilitates compliance preparedness regarding the IT, legal, finance, and audit aspects of the business.

5 Principles of Six Sigma

Focus on the Customer

Every business exists to serve its customers. Therefore, customers must be at the center of every business decision. This requires setting up quality standards that are in line with customer needs.

Analyze the Value Chain and Find Your Problem

Define the steps in a process and identify the unnecessary areas. Equipped with clearly-specified goals, collect data on the problem areas. Analyze this data to arrive at the root cause of your problems.

Eliminate Variations and Resulting Defects

With problem areas discovered, make changes in the process to eliminate variations. Any activity that doesn’t contribute value to customers must be re-evaluated and discarded if required. In the event the value chain analysis doesn’t yield any positive results, companies can use various tools to determine the process bottlenecks.

Increase Stakeholder Involvement

Create a well-structured process that enables your team members to contribute in tune with their expertise and experience. It’s vital to familiarize the team with the types of project management methodologies being used. To this end, companies must impart necessary training to the team to anticipate and tackle failures, and ensure smooth flow of processes.

Facilitate a Responsive Environment

As change is implemented in a process, the corresponding employee effort must change too. It’s this iterative improvement that can help companies maximize process efficiencies. There must be a concerted effort to improve department-level preparedness to promptly adapt to change. This level of agility in response to change gives companies a big competitive edge.

Methodology of Six Sigma

The Six Sigma methodology comprises 5 phases, forming the DMAIC acronym, as mentioned below:

Define how the problem the customer faces can be solved. Define how the project requirements align with the customer expectations. In this phase, companies conduct research and fix the project scope.

Measure how well the current processes are performing. Collect data on defects and compare baseline expectations on performance with the actual performance.

Analyze the process and determine why and where the variations occur. Using data, companies must identify the inputs that affect the final outcomes the most.

Improve the process by locating and eliminating the root causes of defects. Companies must test the alternatives on the basis of cost, implementation ease, risks and performance.

Control the newly-iterated processes and preempt fallback into old ways. Document the process changes, root causes of previous defects, and set a schedule for continuous monitoring.

Six Sigma Techniques

Here are some select Six Sigma techniques that are most commonly used.

Voice of the Customer

Collect all-round feedback from customers, both directly and indirectly. The objective is to not just deliver what the customer demands, but also go beyond and suggest improvements in line with industry trends. The idea is to get all this done in the “Define” part of the above DMAIC process.

5 Whys

Reiterate the question “why” 5 times in a row. Ask “why” in regard to a problem. Re-apply “why” to the resultant answer. And do this 5 times in a row until you dig into the deepest root of the problem. This aspect is best done in the “Analyze” part of the DMAIC process.

Kaizen

It stands for driving continuous improvement to eliminate waste and defects. Once these improvements are identified and implemented, the results are quantified and monitored. This makes it easy to promptly respond to the discovery of the minutest error.

Poka-yoke

Derived from the Japanese term that signifies “error proofing”, it’s an attempt to preempt the possibilities that result in mistakes. It’s particularly useful in the product development stage as it helps proactively identify and eliminate defects, errors, and other unwanted variations.

Value Stream Mapping (VSM)

These are visual maps that enable easy understanding of the process and help determine potential problems. They’re helpful in planning for a future project as they map the existing information and resources. In addition, they also eliminate waste and other inefficiencies along the value chain.

Brainstorming

It’s critical to gather all the ideas shared in a team and analyze them with a collective lens. This can be done through an open session with a moderator to streamline the proceedings.

What Is Lean Six Sigma?

Combining the best of the two most popular process improvement techniques, Lean and Six Sigma, results in Lean Six Sigma. It unites the Six Sigma methods and the lean manufacturing philosophy to reduce wasteful use of time, effort and resources.

Any effort or resource, the lack of which makes no tangible difference to customer value, is re-evaluated and rejected if necessary. Lean facilitates efficiency enhancement by eliminating such non or low-value activities. This, in turn, enables streamlining of processes, which iteratively drives more value with less effort.

By gaining the best of both worlds, Lean Six Sigma is capable of serving the needs of a wide range of industries, including IT services, healthcare, finance and manufacturing among others.

What’s the Difference Between Six Sigma and Lean Six Sigma?

Lean Six Sigma combines the aspects of Lean and Six Sigma to differ from the latter in many ways as follows:

| Six Sigma | Lean Six Sigma |

|---|---|

| It’s a program | It’s both a program and a philosophy |

| Not designed to implement organizational culture change | Designed to reorganize the culture and employee dynamics |

| Focuses on revamping the process to remove defects or waste that can impact quality | Focuses on speeding up processes as well as removing waste |

| Developed for customers and the end products | Developed for waste elimination and improvement of production methods |

| Special-purpose teams are required to implement this | Entire process members are required to implement this |

Real-World Examples of Six Sigma Application

Motorola

It’s at Motorola that Six Sigma was first introduced in the mid 1980s in response to product defects and customer dissatisfaction. To salvage their business advantage, they innovated this methodology for process improvement.

By applying Six Sigma, the company determined why and how the defects were caused, and progressively improved their production processes. All these led to significantly better product quality and customer delight, and restored the company’s brand and performance.

Microsoft

Microsoft has been using Six Sigma for a wide range of initiatives. They leveraged the methodology to identify and reduce defects in their data centers, resulting in iteratively fewer IT infrastructure failures over time until they could eliminate these. The company analyzed high-severity incidents of server failures and elicited suggestions for improvement from the product and security teams.

By applying Six Sigma principles, Microsoft successfully improved their server availability and reliability, thereby improving customer delight.

Ford Motors

In the late 1990s, Ford aimed to go beyond automobile manufacturing, and wanted to become a consumer products company. Their goal was to improve their product quality and customer delight levels.

Using Six Sigma, Ford was able to eliminate more than $2.19 billion in waste over the last 15 years. Buoyed by the successes, Ford undertook almost 10,000 improvement projects since the early 2000s. They also managed to increase their customer satisfaction by 5 percentage points.

Six Sigma Certifications

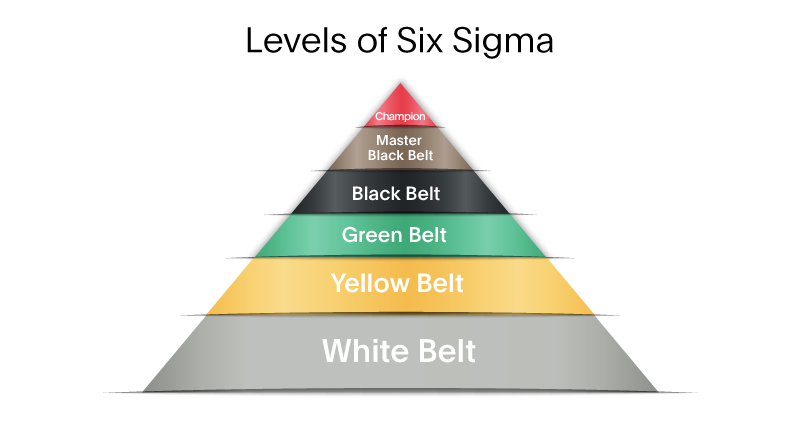

Today, several levels of certifications are available for people who complete programs that may include written exams.

Master Belt

These professionals have achieved the highest Six Sigma level. They provide leadership, strategies, metrics, and training material for black and green belts.

Black Belt

These professionals possess strong expertise in the latest Six Sigma practices. They demonstrate the ability to manage teams and are committed to continuous process and quality improvement.

Green Belt

These professionals have a proven ability to grasp advanced analysis and solve quality-related problems. They have shown themselves capable of leading projects for at least 3 years.

Yellow Belt

These professionals understand how Six Sigma works at a basic level, and are capable of applying the techniques to support teams on analysis.

White Belt

These professionals understand the basics of Six Sigma. They provide assistance to teams in their endeavors: whether it’s quality and process improvement, or change management.

Conclusion

Quality improvement is a complex process that may require one or more methodologies for continued success with customer satisfaction. With Six Sigma, an organization can certainly expect to meet high levels of quality and process excellence similar to those cited in the real-world success stories we’ve discussed here. In conclusion, all it requires is implementation of the right techniques and focusing on the principles to attain the desired level of near-perfection that this methodology promises.